Certified Company

ISO 9001:2005NitroMetal: Empowering Connections with Brass Busbars

.jpg)

NitroMetal, a name synonymous with excellence, introduces its line of Brass Busbars, crafted to empower seamless connections in various industries. With a relentless pursuit of quality and innovation, NitroMetal Brass Busbars offer unparalleled conductivity, durability, and versatility. Engineered to withstand the most demanding environments, our Brass Busbars ensure reliable power distribution and transmission, making them indispensable in energy management, automotive, telecommunications, and beyond. Trust NitroMetal to fuel your connections with precision and reliability, setting new standards of excellence in every application.

Key Features

Explore the outstanding features of our NitroMetal Brass Busbars

-

Exceptional Conductivity:

NitroMetal Brass Busbars boast outstanding electrical conductivity, facilitating efficient power transmission with minimal resistance. This ensures optimal performance and energy efficiency across various applications.

-

Superior Corrosion Resistance:

Engineered with premium-grade brass alloys, our busbars exhibit exceptional resistance to corrosion, oxidation, and environmental factors. This extends their lifespan and reliability, even in harsh operating conditions.

-

Precision Engineering:

NitroMetal employs state-of-the-art manufacturing processes and stringent quality controls to achieve precise dimensions and uniformity in every Brass Busbar. This ensures seamless integration and consistent performance in diverse installations.

-

Versatile Applications:

Designed to meet the demands of a wide range of industries, NitroMetal Brass Busbars find applications in energy management, power distribution, automotive, telecommunications, and more. Their versatility makes them an indispensable component in various systems and infrastructures.

-

Ease of Installation:

NitroMetal Brass Busbars are engineered for ease of installation, featuring standardized dimensions and user-friendly configurations. This simplifies assembly and maintenance tasks, reducing downtime and labor costs for our customers.

-

Compliance and Certification:

NitroMetal Brass Busbars adhere to stringent quality standards and regulatory requirements, ensuring compliance with industry specifications and safety standards. Each busbar is backed by comprehensive testing and certification, providing peace of mind to our customers regarding performance and reliability.

Brass Busbar Material Specifications:

| Specification | Details |

|---|---|

| Material | High-quality brass alloys |

| Standard Compliance | JIS H3250-2006, ASTM B152M, GB/T2040-2008 |

| Dimensions | Various widths and lengths available; Standard: 360260160 mm (Width), 215 mm (Length) |

| Corrosion Resistance | High resistance to corrosion, oxidation, and environmental factors |

| Plasticity and Formability | Excellent plasticity for shaping and forming |

| Processing Capability | Suitable for cold and hot processing techniques; capable of welding, forging, and tin plating |

| Electrical Conductivity | Superior conductivity for efficient power transmission |

Brass Busbar Mechanical Specifications:

| Specification | Details |

|---|---|

| Material | High-quality brass alloys |

| Tensile Strength | Typically ranges from 310 to 380 MPa (45,000 to 55,000 psi) |

| Yield Strength | Approximately 160 to 250 MPa (23,000 to 36,000 psi) |

| Elongation | Typically 40% to 50% in 50 mm (2 inches) |

| Hardness | Varies depending on alloy composition and heat treatment; commonly ranges from 65 to 100 HRB (Rockwell B) |

| Impact Resistance | Resilient to mechanical shocks and impacts; provides reliable performance under dynamic loads |

Types of Brass Busbar Available

-

Solid Brass Busbars:

These busbars are made from a single, solid piece of brass material, offering excellent conductivity and durability. They are commonly used in applications requiring high current-carrying capacity and stability.

-

Hollow Brass Busbars:

Featuring a hollow center, these busbars reduce material usage while maintaining strength. They are suitable for applications where weight reduction is important, offering good conductivity and mechanical performance.

-

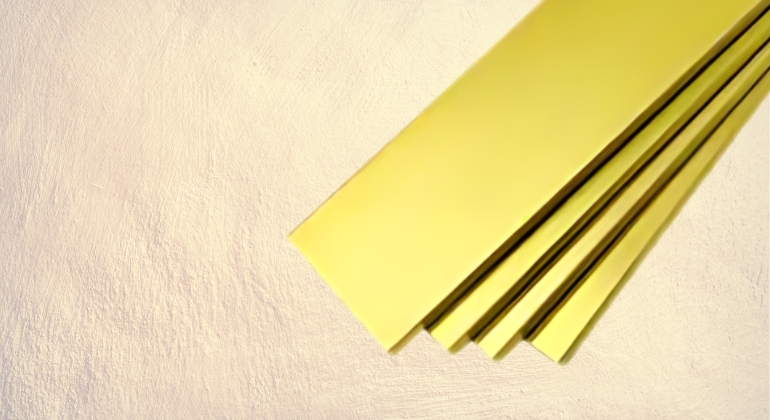

Flat Brass Busbars:

With a flat, rectangular cross-section, these busbars provide a uniform contact area for electrical connections. They are ideal for applications where space is limited or where a flush mounting surface is required.

-

Round Brass Busbars:

These busbars have a cylindrical shape, providing increased surface area compared to flat busbars. They are suitable for applications requiring high current-carrying capacity in confined spaces and offer efficient heat dissipation.

-

Twisted Brass Busbars:

Consisting of multiple strands of brass wire twisted together, these busbars offer enhanced flexibility and mechanical strength. They are ideal for applications where vibration or movement is a concern.

-

Custom Brass Busbars:

These busbars can be manufactured to meet specific design requirements, offering flexibility in dimensions, shapes, and configurations. They are ideal for bespoke applications where standard busbars may not suffice.

Applications & Uses of Brass Busbar

- Power Distribution Systems

- Electrical Panels and Switchgear

- Industrial Machinery and Equipment

- Renewable Energy Systems (Solar, Wind)

- Automotive and Transportation Vehicles

- Telecommunications Infrastructure

- Electrical Grounding and Earthing Systems

- Power Generation Facilities

- Marine and Offshore Installations

- Data Centers and Server Rooms

Service Result

Get personalized guidance from our knowledgeable team to make informed decisions about our products.

Tailor our products to your unique needs with assistance in adapting dimensions, materials, and finishes.

Enjoy ongoing assistance for troubleshooting, installation, and product maintenance, ensuring seamless operations.