Certified Company

ISO 9001:2005Comprehensive Guide to Copper Sheet for Nitro Metals

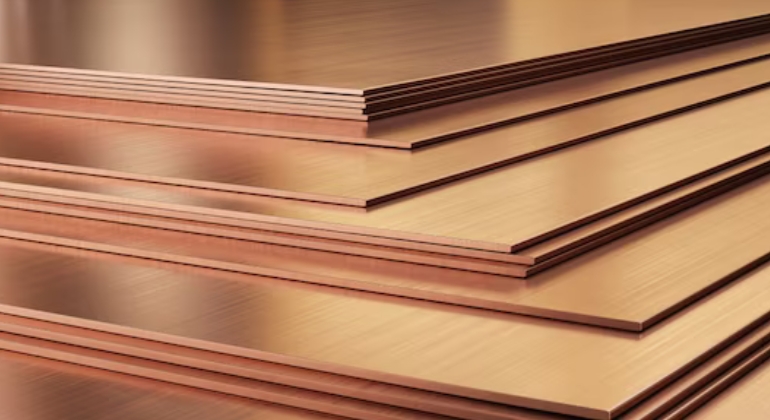

Copper sheet, with its distinctive reddish-brown hue, is a highly versatile and malleable material widely used across various industries. Renowned for its excellent thermal and electrical conductivity, copper sheets are an essential component in applications ranging from electrical equipment, roofing, plumbing, to decorative arts. This guide provides an in-depth look at the key features, specifications, mechanical properties, types, and applications of copper sheets, tailored for Nitro Metals's diverse industrial needs.

Key Features

Explore the outstanding features of our Copper Srtip

-

High Electrical Conductivity:

Copper sheets offer superior electrical conductivity, making them ideal for use in electrical components and conductive applications.

-

Thermal Conductivity:

With its excellent ability to transfer heat, copper is perfect for heat exchangers, radiators, and cooling systems.

-

Corrosion Resistance:

Copper naturally resists corrosion, ensuring durability in harsh environments and extending the lifespan of products.

-

Malleability and Ductility:

Easily shaped, bent, and formed, copper sheets can be customized for various applications without compromising strength.

-

Aesthetic Appeal:

The unique color and sheen of copper make it a preferred choice for architectural and decorative applications.

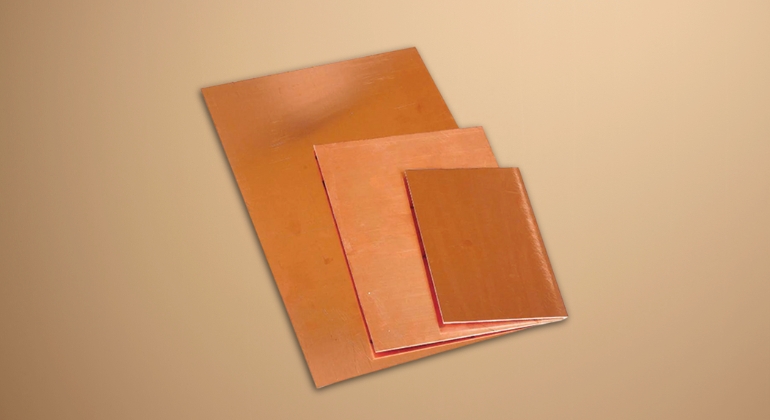

Copper Sheet Specifications:

| Property | Value |

|---|---|

| Thickness | 0.5mm - 10mm |

| Width | Up to 3000mm |

| Length | Up to 8000mm |

| Conductivity | >101% IACS |

| Thermal Conductivity | 398 W/mK |

| Melting Point | 1085°C |

Copper Sheet Mechanical Specifications:

| Mechanical Property | Specification |

|---|---|

| Tensile Strength | 200 - 250 MPa |

| Yield Strength | 60 - 90 MPa |

| Elongation | 45 - 50% |

| Hardness (Brinell) | 60 - 90 HB |

Types of Copper Sheets Available

-

C110 Copper Sheet (Electrolytic Tough Pitch):

This is the most common type of copper sheet, offering high electrical conductivity, making it ideal for electrical and electronic applications.

-

C101 Copper Sheet (Oxygen-Free):

With almost no oxygen content, this type provides enhanced conductivity and ductility. It's perfect for applications requiring welding, brazing, and a high degree of corrosion resistance.

-

Copper Alloy Sheets (Brass, Bronze):

By combining copper with other elements like zinc or tin, these sheets offer tailored properties for specific needs, including enhanced strength, resistance to wear, and a unique appearance.

-

Pre-Patinated Copper Sheets:

These sheets undergo a controlled oxidation process to achieve a verdigris or patina finish, offering an aesthetic advantage for architectural applications without waiting for natural weathering.

Applications & Uses of Copper Sheet

- Electrical components and conductors

- Architectural roofing and cladding

- Heat exchangers and radiators

- Plumbing fittings and fixtures

- Decorative arts and crafts

Service Result

Get personalized guidance from our knowledgeable team to make informed decisions about our products.

Tailor our products to your unique needs with assistance in adapting dimensions, materials, and finishes.

Enjoy ongoing assistance for troubleshooting, installation, and product maintenance, ensuring seamless operations.