Certified Company

ISO 9001:2005Nitro Metals Brass Coils & Circles

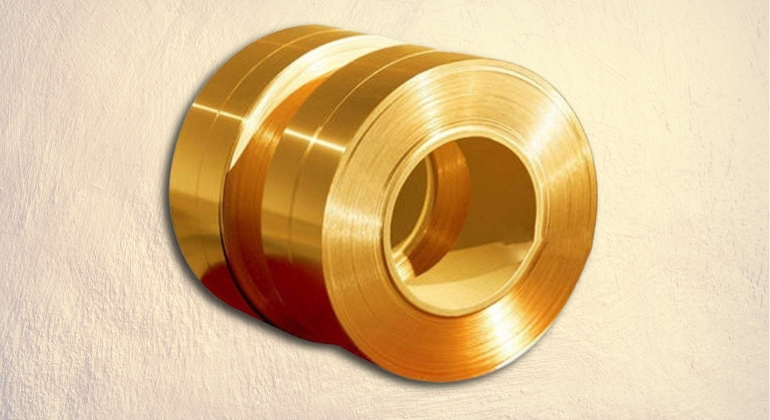

Our Nitro Metals coils, and circles are manufactured using the highest quality raw materials, ensuring exceptional durability and versatility. We are dedicated to delivering value without compromising on the distinctive qualities of our nitro metal products. Rigorous quality control measures and advanced manufacturing processes guarantee that our Nitro Metals products meet the highest industry standards.

Key Features

Explore the outstanding features of our Brass Coils

-

High Malleability and Ductility:

Brass coils can be easily shaped and formed into various configurations, making them ideal for complex manufacturing processes.

-

Excellent Corrosion Resistance:

Brass offers superior resistance to corrosion, particularly in marine and industrial environments, ensuring long-lasting performance.

-

Good Tensile Strength:

With its robust tensile strength, brass coils provide durability and reliability for applications requiring strong, resilient materials.

-

Distinctive Golden Color:

The appealing golden hue of brass makes it a popular choice for decorative and ornamental applications, adding aesthetic value to products.

-

Wide Range of Applications:

Brass coils are versatile and used in numerous industries, including plumbing, electrical connectors, musical instruments, and hardware fittings.

-

Consistent Quality and Tolerances:

Manufactured with stringent quality control, brass coils maintain precise dimensions and consistent properties, ensuring reliable performance in all applications.

Brass Coil Specifications:

| Feature | Specification Details |

|---|---|

| Thickness Range | 0.04 mm to 2.5 mm |

| Width Range | 8.0 mm to 406.4 mm (16") |

| Alloy Compositions | Cu/Zn: 60/40, 63/37, 67/33, 70/30, 80/20, 85/15, 90/10 |

| Temper Options | DD, Soft, QH, HH, 3/4H, H, EH, SH |

| Coil Inner Diameter | 100 mm, 150 mm, 200 mm, 300 mm, 400 mm |

| Typical Applications | Hardware fittings, ornamental hardware, decorations, musical instruments, plumbing, marine hardware, handicrafts, hot water geysers, utensil manufacturing, electrical connectors, radiators, ordnance |

| Mechanical Properties | High malleability and ductility, good tensile strength, excellent corrosion resistance |

| Surface Finish | Smooth, polished, available in various finishes |

| Quality Control | Stringent quality checks to ensure consistency and reliability |

| Tolerance (Thickness) | +/- 0.003 mm to +/- 0.040 mm |

| Tolerance (Width) | +/- 0.10 mm to +/- 0.50 mm |

Brass Coil Mechanical Specifications:

| Property | Specification Details |

|---|---|

| Tensile Strength | Typically ranges from 300 MPa to 500 MPa, depending on the alloy and temper |

| Yield Strength | Varies by alloy and temper, generally between 100 MPa and 300 MPa |

| Elongation | Typically ranges from 10% to 45%, depending on the temper and alloy |

| Hardness | Varies by alloy and temper, typically measured in HV (Vickers Hardness) from 50 to 150 HV |

| Density | Approximately 8.4 g/cm³ |

| Thermal Conductivity | Ranges from 100 to 150 W/m·K, depending on the alloy |

| Electrical Conductivity | Approximately 28% to 37% IACS (International Annealed Copper Standard) |

| Corrosion Resistance | Excellent, particularly in marine and industrial environments |

| Melting Point | Typically around 900°C to 940°C, depending on the alloy composition |

| Modulus of Elasticity | Approximately 100 GPa |

| Coefficient of Thermal Expansion | Approximately 20 x 10⁻⁶ /°C |

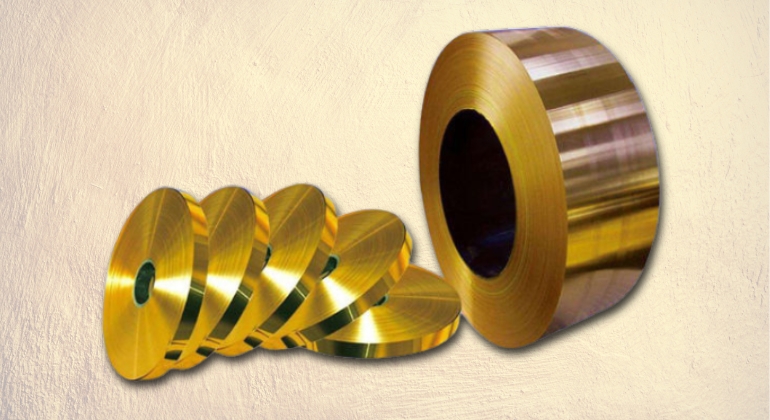

Types of Brass Coil Available

-

60/40 Brass Coil:

Brass coils are available in various compositions to cater to a wide range of industrial and commercial applications. The 60/40 brass coil, comprising 60% copper and 40% zinc, is commonly utilized in industries requiring precision and reliability, such as ordnance, electrical components, and detonators. With its balanced ratio, it offers excellent electrical conductivity and mechanical strength, making it suitable for demanding environments.

-

63/37 Brass Coil:

Similarly, the 63/37 brass coil, featuring 63% copper and 37% zinc, is prized for its versatility and corrosion resistance. It finds extensive use in electrical fittings, hardware components, and decorative applications due to its superior formability and aesthetic appeal. This alloy strikes a balance between strength and ductility, making it ideal for intricate designs and precision engineering.

-

70/30 Brass Coil:

In contrast, the 70/30 brass coil, consisting of 70% copper and 30% zinc, is valued for its exceptional corrosion resistance and malleability. It is widely employed in plumbing fixtures, marine hardware, and architectural elements where durability and aesthetics are paramount. The 70/30 alloy offers excellent resistance to tarnishing and atmospheric corrosion, ensuring longevity in harsh environments.

-

80/20 Brass Coil:

Moving on to the 80/20 brass coil, characterized by 80% copper and 20% zinc, it is favored for applications requiring high conductivity and thermal stability. Common uses include musical instruments, radiator tanks, and electrical connectors, where its superior acoustic properties and heat dissipation capabilities are highly desirable.

-

85/15 Brass Coil:

Similarly, the 85/15 brass coil, composed of 85% copper and 15% zinc, offers exceptional machinability and weldability, making it suitable for various manufacturing processes. It is commonly employed in utensil manufacturing, hot water geysers, and mechanical components where ease of fabrication and corrosion resistance are essential.

-

90/10 Brass Coil:

Lastly, the 90/10 brass coil, featuring 90% copper and 10% zinc, is renowned for its high tensile strength and wear resistance. It finds applications in precision engineering, lock and key manufacturing, and watchmaking, where its durability and aesthetic qualities are valued. This alloy is known for its excellent polishability and ability to retain its luster over time, making it a preferred choice for decorative and functional purposes.

Applications & Uses of Brass Coil

- Ordnance

- Electrical Components

- Detonators

- Precision Instruments

- Hardware Fittings

- Electrical Connectors

- Automotive Components

Service Result

Get personalized guidance from our knowledgeable team to make informed decisions about our products.

Tailor our products to your unique needs with assistance in adapting dimensions, materials, and finishes.

Enjoy ongoing assistance for troubleshooting, installation, and product maintenance, ensuring seamless operations.