Certified Company

ISO 9001:2005Nitro Metals: Your Premier Brass Sheet Manufacturer and Exporter

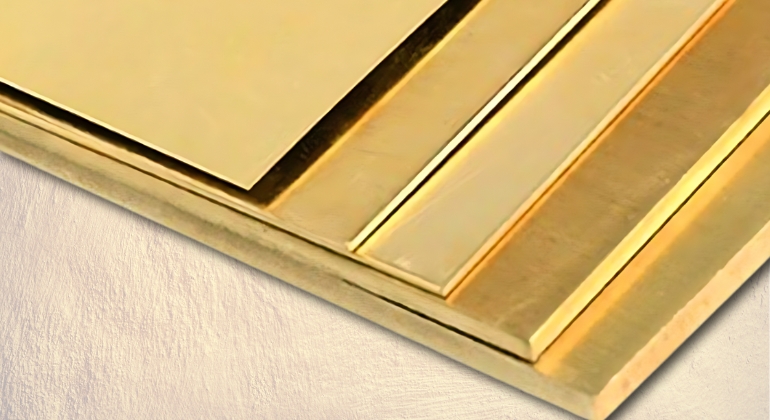

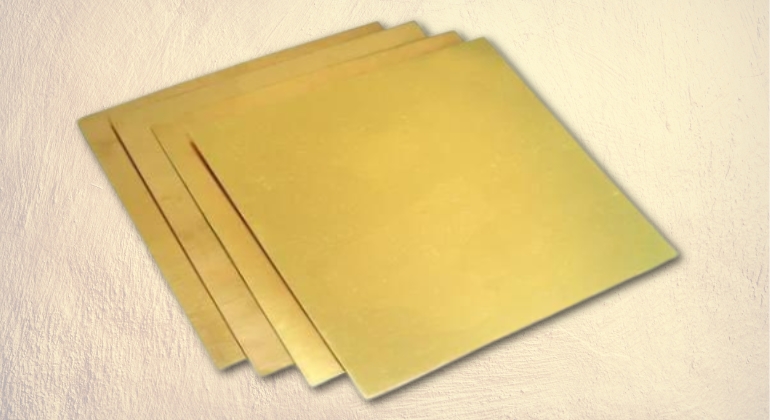

Nitro Metals offers a diverse selection of brass sheets suitable for various applications. Our product range includes a variety of alloys, ensuring that clients can find the perfect match for their specific needs. We offer customization to meet unique requirements, from standard dimensions to specialized finishes.

Our brass sheets adhere to stringent international standards, ensuring top-notch performance and reliability. We offer the option for tighter tolerances upon request, underscoring our commitment to quality.

Key Features

Explore the outstanding features of our Nitro Metals Brass Sheets

-

Comprehensive Product Range:

Nitro Metals offers a diverse selection of brass sheets suitable for various applications. Our product range includes a variety of alloys, ensuring that clients can find the perfect match for their specific needs. We offer customization to meet unique requirements, from standard dimensions to specialized finishes.

-

High-Quality Standards:

Our brass sheets adhere to stringent international standards, ensuring top-notch performance and reliability. We offer the option for tighter tolerances upon request, underscoring our commitment to quality.

-

Customization and Finishing Options:

We provide multiple platings, coatings, edge conditioning, and special surface finishes, enabling us to tailor our brass sheets to the unique specifications of customers across various industries.

-

Mechanical and Physical Specifications:

Our brass sheets are known for their excellent mechanical properties, such as hardness, tensile strength, yield strength, and elongation percentages. They also feature desirable physical properties like density, electrical and thermal conductivity, and modulus of elasticity, ensuring optimal performance in a wide range of applications.

-

Wide Application Spectrum:

Nitro Metals's brass sheets are versatile and find usage in numerous sectors, including electrical and electronics, construction, plumbing, automotive, textile accessories, defense, and decorative fittings. This versatility attests to the adaptability and quality of the brass sheets we offer.

-

Global Standards and Types:

Our brass sheets are produced in accordance with various international norms, ensuring compatibility and recognition across global markets. Nitro Metals offers different types of brass, such as alpha, alpha-beta, high-zinc beta, leaded, naval, yellow, and red brass, each with unique specifications and properties suitable for distinct applications.

Specifications for Nitro Metals Brass Sheets

| Alloy Type | Composition | Hardness (HB) | Tensile Strength (N/mm²) | Yield Strength (N/mm²) | Elongation (%) |

|---|---|---|---|---|---|

| Alpha Brass (CuZn) | 55-65% Cu, 35-45% Zn | 80-150 | 300-600 | 100-350 | 30-45 |

| Alpha-Beta Brass (CuZn40) | 60% Cu, 40% Zn | 90-160 | 350-700 | 150-400 | 25-40 |

| High-Zinc Beta Brass (CuZn15) | 15% Cu, 85% Zn | 100-180 | 400-750 | 200-450 | 20-35 |

| Leaded Brass (CuZn39Pb3) | 58-63% Cu, 35-40% Zn, 2-3% Pb | 70-140 | 300-550 | 90-300 | 30-40 |

| Naval Brass (CuZn40Sn1) | 60% Cu, 39% Zn, 1% Sn | 90-160 | 350-700 | 150-400 | 25-40 |

| Yellow Brass (CuZn33) | 67% Cu, 33% Zn | 80-150 | 300-600 | 100-350 | 30-45 |

| Red Brass (CuZn15) | 85% Cu, 15% Zn | 90-170 | 350-650 | 150-400 | 25-35 |

Mechanical Specifications for Nitro Metals Brass Sheets

| Alloy Type | Hardness (HB) | Tensile Strength (N/mm²) | Yield Strength (N/mm²) | Elongation (%) |

|---|---|---|---|---|

| Alpha Brass (CuZn) | 80-150 | 300-600 | 100-350 | 30-45 |

| Alpha-Beta Brass (CuZn40) | 90-160 | 350-700 | 150-400 | 25-40 |

| High-Zinc Beta Brass (CuZn15) | 100-180 | 400-750 | 200-450 | 20-35 |

| Leaded Brass (CuZn39Pb3) | 70-140 | 300-550 | 90-300 | 30-40 |

| Naval Brass (CuZn40Sn1) | 90-160 | 350-700 | 150-400 | 25-40 |

| Yellow Brass (CuZn33) | 80-150 | 300-600 | 100-350 | 30-45 |

| Red Brass (CuZn15) | 90-170 | 350-650 | 150-400 | 25-35 |

Types of Brass Sheet Available

-

Alpha Brass (CuZn):

Comprising 55-65% copper and 35-45% zinc, Alpha Brass is ideal for cold working processes. Its high copper content provides good corrosion resistance and excellent formability, making it suitable for applications requiring intricate shapes and fine details.

-

Alpha-Beta Brass (CuZn40):

With approximately 60% copper and 40% zinc, Alpha-Beta Brass is known for its balanced strength and ductility. This alloy offers good machinability and is often used in applications where moderate strength and excellent corrosion resistance are required.

-

High-Zinc Beta Brass (CuZn15):

Containing around 15% copper and 85% zinc, High-Zinc Beta Brass is prized for its strength. It is commonly used in applications that demand high tensile strength and resistance to wear, such as fittings and fasteners.

-

Leaded Brass (CuZn39Pb3):

This alloy includes 58-63% copper, 35-40% zinc, and 2-3% lead. The addition of lead improves machinability, making Leaded Brass ideal for precision components and high-speed machining operations. It is often used in the manufacturing of valves, fittings, and other hardware.

-

Naval Brass (CuZn40Sn1):

Naval Brass contains 60% copper, 39% zinc, and 1% tin. The tin content enhances resistance to dezincification and corrosion, especially in seawater environments. This makes it a preferred choice for marine applications, such as shipbuilding and underwater hardware.

-

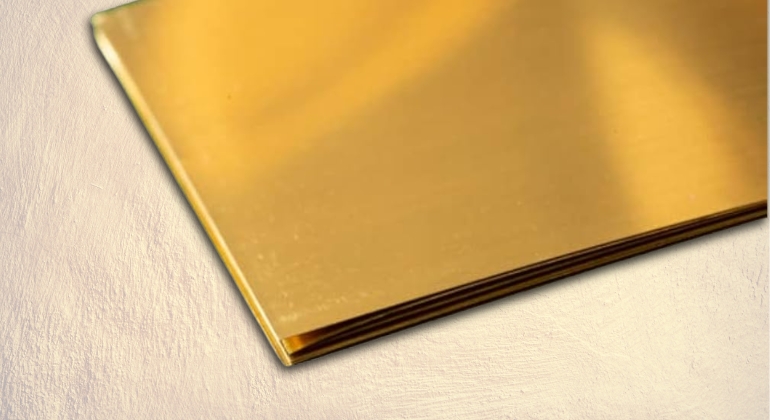

Yellow Brass (CuZn33):

Known for its bright yellow color, Yellow Brass consists of about 67% copper and 33% zinc. It combines good strength with excellent ductility and is often used for decorative applications, musical instruments, and plumbing fixtures due to its attractive appearance and ease of fabrication.

-

Red Brass (CuZn15):

With a composition of 85% copper and 15% zinc, Red Brass is notable for its reddish color and excellent corrosion resistance. It is commonly used in applications requiring durability and aesthetics, such as architectural fittings, plumbing, and electrical components.

Applications & Uses of Brass Strip

- Electrical and Electronics Industry

- Construction

- Plumbing

- Automotive

- Textile Accessories

- Defense

- Decorative Fittings

- Marine Applications

- Musical Instruments

- Valves and Fittings

- Precision Components

- Architectural Fittings

- Electrical Components

Service Result

Get personalized guidance from our knowledgeable team to make informed decisions about our products.

Tailor our products to your unique needs with assistance in adapting dimensions, materials, and finishes.

Enjoy ongoing assistance for troubleshooting, installation, and product maintenance, ensuring seamless operations.