Certified Company

ISO 9001:2005Premier Supplier of High-Quality

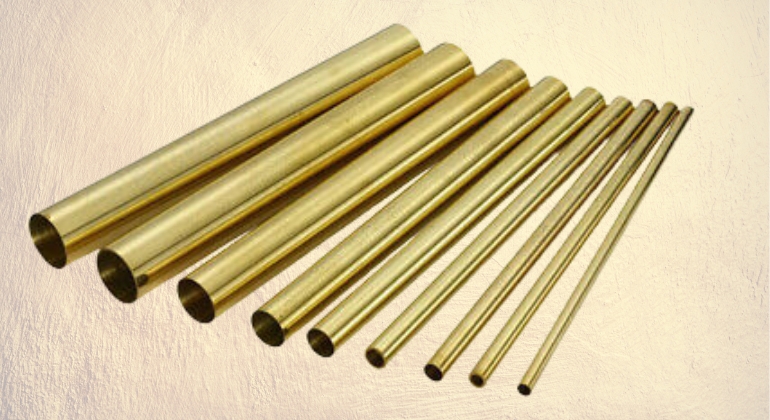

Brass Pipes & Tubes

We are a leading manufacturer, supplier, and exporter of top-quality brass pipes and tubes in various forms, shapes, sizes, dimensions, and other specifications. Utilizing high-grade raw materials and advanced machinery, we produce these brass pipes and tubes according to both Indian and international quality standards.

Key Features

Explore the outstanding features of our Copper Strip

-

Superior Material Composition:

Crafted from copper and zinc alloys with precise ratios, ensuring exceptional corrosion resistance and high tensile strength.

-

Versatile Types Available:

Choose from a wide array of options including Seamless, Welded, ERW, and EFW Brass Pipes & Tubes to suit diverse application needs.

-

Customizable Forms:

Available in Round, Square, Rectangular, and Hydraulic shapes, along with the flexibility for custom designs to meet specific project requirements.

-

Comprehensive Specifications:

Manufactured in compliance with ASTM and ASME standards, offering a range of dimensions, sizes, and surface treatments to match varied project demands.

-

Diverse End Types:

From Plain End to Beveled End to Threaded, our Brass Pipes & Tubes cater to different installation methods, ensuring seamless integration into various systems.

-

Premium Quality Assurance:

Backed by stringent quality control measures at every stage of production, guaranteeing consistent performance and durability in diverse industrial applications.

Brass Tube & Pipe Specifications:

| Specification | Details |

|---|---|

| Standards | ASTM B135, ASME SB135, ASTM B36, ASME SB36 |

| Pipe Size | 15mm NB to 150mm NB (1/2″ to 6″), up to 7″ (193.7mm OD to 508mm OD) |

| Tube Size | 6 mm OD x 0.7 mm to 50.8 mm OD x 3 mm thickness |

| Outer Diameter | 1.5 mm – 350 mm |

| Thickness | 0.3 – 9 mm |

| Lengths | Double Random, Single Random, Cut Length |

| Surface Treatments | Black painting, varnish paint, anti-rust oil, hot galvanized, cold galvanized, 3PE |

| End Types | Plain End, Beveled End, Threaded |

Brass Tube & pipe Mechanical Specifications:

| Mechanical Property | Details |

|---|---|

| Tensile Strength | 310 - 620 MPa (varies based on alloy and grade) |

| Yield Strength | 110 - 480 MPa (varies based on alloy and grade) |

| Elongation | 15% - 45% (varies based on alloy and grade) |

| Hardness | 40 - 100 HRB (varies based on alloy and grade) |

| Density | 8.4 - 8.7 g/cm³ (varies based on alloy and grade) |

| Modulus of Elasticity | 90 - 120 GPa (varies based on alloy and grade) |

| Thermal Conductivity | 100 - 150 W/m·K (varies based on alloy and grade) |

| Melting Point | 900 - 940°C (varies based on alloy and grade) |

Types of Copper Sheets Available

-

Seamless Brass Pipes & Tubes:

Manufactured without any welding, providing a smooth and uniform structure. Ideal for high-pressure applications due to their strength and durability.

-

Welded Brass Pipes & Tubes:

Created by welding brass sheets or plates together, making them cost-effective and suitable for lower-pressure applications.

-

ERW (Electric Resistance Welded) Brass Pipes:

Produced using electric resistance welding, offering precise dimensions and a smooth finish. Commonly used in construction and engineering projects.

-

EFW (Electric Fusion Welded) Brass Pipes:

Made by electric fusion welding, known for their high strength and excellent corrosion resistance. Used in industries requiring reliable and durable piping.

-

Hot Finished Brass Pipes:

Manufactured using hot working processes, resulting in enhanced toughness and mechanical properties. Suitable for applications requiring high strength.

-

Cold Finished Brass Tubes:

Created through cold working processes, providing a smooth surface finish and tighter dimensional tolerances. Preferred for precision engineering and decorative applications.

Applications & Uses of Brass Coil

- Plumbing Systems

- Heating and Cooling Systems

- Marine Applications

- Architectural and Structural Applications

- Decorative Purposes

- Electrical Conduits

- Heat Exchangers

- Automotive Components

- Industrial Machinery

- Musical Instruments

Service Result

Get personalized guidance from our knowledgeable team to make informed decisions about our products.

Tailor our products to your unique needs with assistance in adapting dimensions, materials, and finishes.

Enjoy ongoing assistance for troubleshooting, installation, and product maintenance, ensuring seamless operations.